Nesting and Optimization Software : PLUS 2D

White Papers

| General | Glass Industry | Woodworking Industry | Sheet Metal Fabrication | Paper | ACP, SIP Plastics | Stones | Others |

| Descriptions | ||||||||||

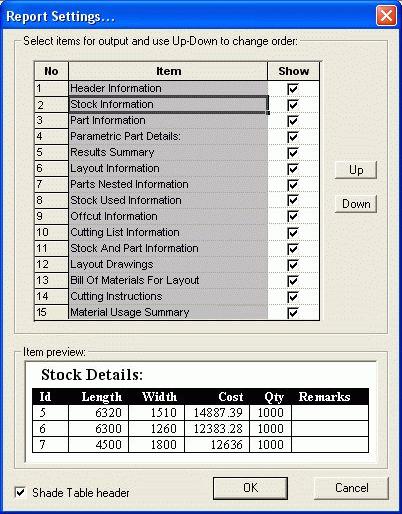

During optimization of the parts there are different thing which you need in output. PLUS 2D provides facility of customizing output report. There are some options given below which are coming in output. The option which you want can select by marking on check box in front it. Also if you want to change the order you can move the row using up and down button. See the Report Setting Dialog to customize the output.

|

|

|||||||||

|

Offcut - a reusable parts that remains from an earlier job. In PLUS 2D during the nesting if you are using offcut as stock then what it will do is, it tries to use the offcut first in such a way that its utilization will be good. Only then it will pick the prime stock. |

||||||||||

|

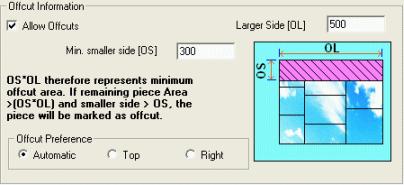

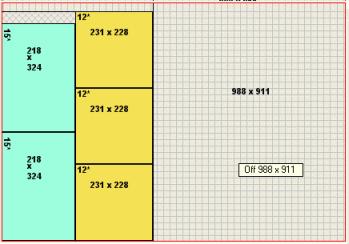

PLUS 2D has an option ' Allow Offcut', where you can specify the minimum area of the Offcut. If during optimization in any optimized layout contains unutilised area having size equal or more than that, then it is considered as a offcut and it is tracked by PLUS 2D. Here min offcut size specified is 500*300 and See the offcut tracked in the layout. Here offcut size is 988 * 911.

|

|

|||||||||

|

Tracking of Offcut |

||||||||||

|

Re-nest - is a special option provided in PLUS 2D. For a particular job after nesting if you don't like the some layouts (more than one ) or you feel there is a better alternative, then you can reject such layouts and Re-Nest that. For details Click Here!! |

||||||||||

|

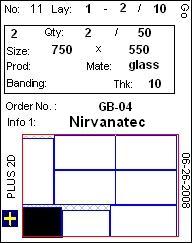

If each part has a label to identify the customer to which is made, its dimensions, etc. tracking problems are resolved. You can add an option to PLUS 2D - link it

with PLUS Label Maker software. This will allow you to make Bar Coded Labels at a click of a button. You can print labels using an ordinary Inkjet, Laser or even Thermal Printer. PLUS Label Maker will print to nearly all PC compatible printers on any type of paper |

||||||||||

|

PLUS Label Maker |

|||||||||

|

PLUS 2D export the layout drawings as DXF with information on different layers which you can import into your cutting table link software. We also write out the data in standard formats. To know whether your CNC controller is supported or not Click Here!! Also if you have any table and to use PLUS 2d along with that please contact with for customization.

|

||||||||||

|

PLUS 2D supports links to many CNC cutting machine. To check the list of available Click Here!! If machine you are using is not available in our list you can contact us with machine detail. We will customize PLUS 2D to interface its output with you machine. We can also offer PLUS 2D as an OEM solution with your saw or cutting table or shearing machine. Please get in touch with us. |

||||||||||

|

Pattern amendment allows you to edit the nested layout. In some case it happens that there is a big offcut generated in a layout where you want to add another part or some part you want to replace by another parts. This optional add on module in PLUS 2D helps you to edit the desired nested layout. |

||||||||||

|

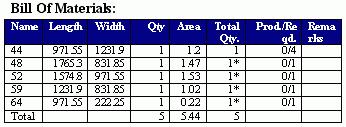

BOMGen - a bill material software is integrated with PLUS 2D. For more details Click Here!! |

||||||||||

When you have more no of part quantity and want to cut that parts from stock so that wastage will be reduce. If you are trying this manually you will face no of problem, need to lots of calculation, wastage of time, insecurity of perfection. To avoid all this simply switch to PLUS 2D, simple understand, take less time to use and give better output. Using PLUS 2D you can save material and time. |

||||||||||

|

PLUS 2D support only 2 dimensional parts. It only do the nesting of two dimensional parts like nesting from panels, boards, sheet, coils and etc.. so you are not able to see the 3D model. |

||||||||||

|

When you are cutting the stocks/boards into

required sizes, you have to use number of pallets to place different

cut sizes in different pallet. Because of this you will have number

of open pallets, that can waste lots of place, time in keeping the

parts on pallets and energy of the workers doing so. Hence overall

it decreases the efficiency of the process, which may further lead

to delays in delivery. |

||||||||||

|

In PLUS 2D you can specify fine define your own column to add information you required for the documentation purpose, Also you can give name to this column so that its easy to recognize. Most beneficial thing is that if you required to add some data in bar coded labels at time also this column are very useful. |

||||||||||

// To Do // Suggest 2dLight |

||||||||||

|

PLUS 2D can be interfaced with many ERP systems like SAP, Ramco, BAAN, etc. Among the services we provide, is the customization to interface with ERP systems. |

||||||||||

|

PLUS 2D give very detail and meaning full output file report using which any person can do the manual cutting and keep the part cut details with it. For more details Click Here!!

|

|

|||||||||