Nesting and Optimization Software - PLUS 2D

White Papers

| General | Glass Industry | Woodworking Industry | Sheet Metal Fabrication | Paper | ACP, SIP Plastics | Stones | Others |

| Descriptions | ||||||||||

|

When you are having multiple stock and using that you want to nest required part quantity, at that time PLUS 2D helps you to choose proper of stock with proper quantity so that your wastage will be minimize. Also if you want to use some stock 1st and then remain this problem can also be solve in PLUS 2D. |

||||||||||

|

The user interface provided in PLUS 2D is so simple and easy to understand, within 5 min you can get the output. You just start the package and do your work from left to right. Only you have to go through Stock , Part, Settings and your output will be ready. Its so easy that by seeing the user interface you can comfortably use it. |

||||||||||

|

PLUS 2D doesn't have limitation on the number of parts that can be nested. You will find that in an other software there is limitation of part to be nested, or it takes much time for higher quantity or result will not be constant. In this there will be no limitation on number of parts and also it take very less time. Another important thing is if you nest again and again, the result will not change, until you change the settings or the stock or the parts. |

||||||||||

|

When you are having multiple stock and using that you want to nest required part quantity, at that time PLUS 2D helps you to choose proper of stock with proper quantity so that your wastage will be minimize. |

||||||||||

|

PLUS 2D helps to estimate the panels/ boards/ sheet (Stock) required for a job. Suppose you have a job ie there are no. of parts you want to nest and the you want to order stock for that. Then you just enter the different stocks in stock pages with some higher quantity and optimize the job. The summary results will show the necessary stock to be ordered - this will be the stocks consumed to complete the job. |

||||||||||

|

PLUS 2D have an option where you can specify margin for stock during its use. Above dialog shows that you can specify margin 3 ways. If you don't want to specify margin then select 'No Margin', for specifying margin in all sides of stock select 'Same Margin on all sides', and to specify different margin in all sides of stock select 'Different Margin on each sides'. |

||||||||||

|

PLUS 2D provide the facility of importing data list (Stock list or part list) from spreadsheet. You can select the data and paste it to a particular table i.e. for stock or part. Lets take an example : Your customer sends some part detail and you want to enter that in to PLUS 2D then copy a column block say the Length and paste it into corresponding column of part table. |

||||||||||

|

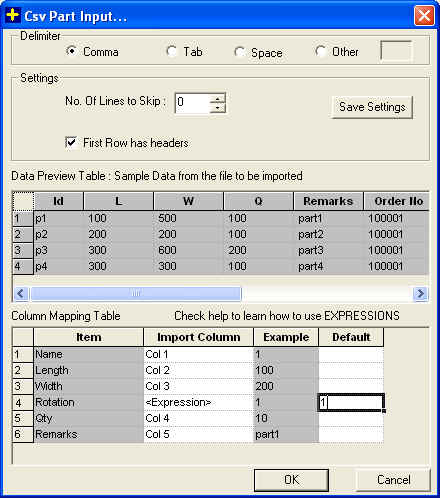

PLUS 2D having a facility of importing data from CSV (Comma separated Variable) file. Its very easy to understand and learn. Import via CSV files, is very flexible as

For more details Click here!! |

|

|||||||||

|

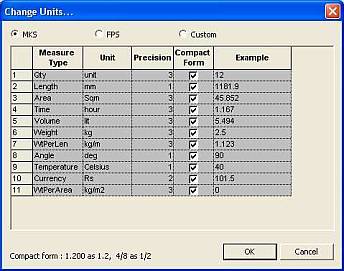

In PLUS 2D you can work in Metric unit or English unit. There is no restriction to work in any specific unit . Also you can switch to any unit though have entered data earlier. Also there is a conversion option to convert any value from one unit to another. See the Unit Setting Dialog.

|

|

|||||||||

Generally in wood working industries you have to consider grain direction. If there are patterns or grains in the panel, part can not be rotated as design on the product will change. An option "Rotation" - whether the part can be rotated or not is provided. Simply uncheck this option, if the part cannot be rotated. |

||||||||||

|

// To Do - Specific to Grating Industry : Need to get input from Tech. guys |

||||||||||

|

The Kerf loss or the cutting loss is considered by PLUS 2D, if the value is provided along with other settings. It very simple what you have to do is that in setting page you will see the one of below Kerf setting value box (It will be according to you industry you will one of below pic.), just add Kerf Value in it before optimization. PLUS 2D Nest the all required parts considering this Kerf value.

|

||||||||||

|

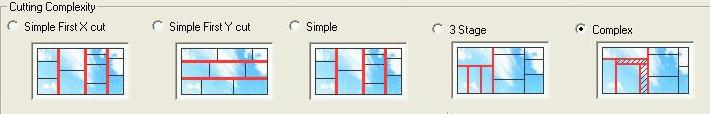

In PLUS 2D user can control over the cutting complexity. There are some cutting complexity options given below. User can prefer any one from five options.

|

||||||||||

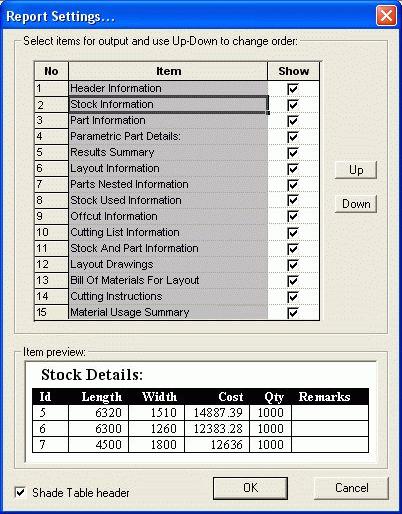

During optimization of the parts there are different thing which you need in output. PLUS 2D provides facility of customizing output report. There are some options given below which are coming in output. The option which you want can select by marking on check box in front it. Also if you want to change the order you can move the row using up and down button. See the Report Setting Dialog to customize the output.

|

|

|||||||||

|

PLUS 2D provides the facility of cut simulation. Cut simulation gives the track about cutting a nested sheet or panel ie how the to cut nested pattern from sheet or panel. Also in output there is a table "Cutting Instruction" which also gives an idea about cutting the parts. |

||||||||||

|

PLUS 2D Standard version has a built in inventory, using which you can enter your available stock. This typically is the shop floor inventory. This is an optional feature in the Light Version. If you want a full-fledged inventory management system, please take a look at our Order Processing & Inventory Management software or Bill of Material Generation software. Click Here!! |

||||||||||

|

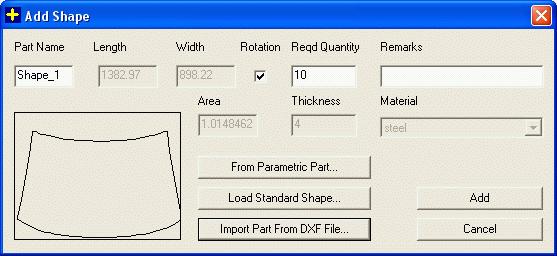

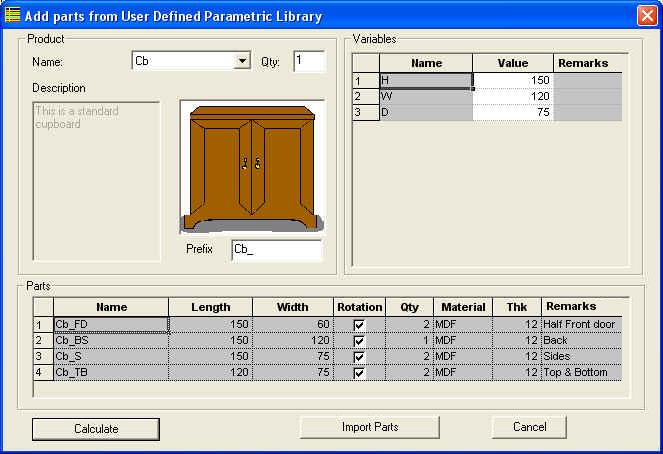

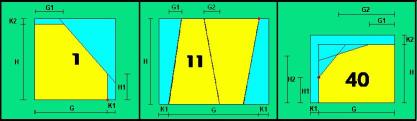

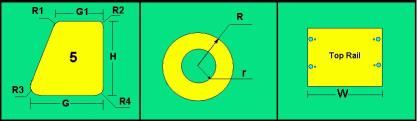

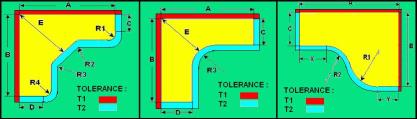

In many cases you require different parametric shapes or non-rectangular shapes. PLUS 2D provides facility of adding shape and optimize these as per the rules. PLUS 2D has built in parametric shapes library which contain different shapes required in :

According to industry requirements, some standard libraries have been made. To use of this library is too easy to enter input your data. Click here!! Pairing of Shapes : some time shape you are adding for optimization can be pair with each there. There are some option given in shapes that allows you to pair shapes or not. To know more about these Click here!!. User Defined Pattern : Like shape pairing provides another option to create you pattern for shapes you have added. For detail information about Pattern Click Here!! Add your Shapes to PLUS 2D Shape Library Package : If you want to add some of your own shape, then please contact us. We will analyze and if feasible, we will do customization to add these shapes to the Library. This may involve commercial discussions.

|

|

|||||||||

|

Shapes for Glass |

||||||||||

|

||||||||||

|

Shapes for Metal |

||||||||||

|

||||||||||

|

Shapes for Wood |

||||||||||

|

|

||||||||||

|

Pairing of Shapes |

||||||||||

|

PLUS 2D has a facility to import CAD base files (DXF files). is very simple and easy thing to add a CAD drawing parts to nest. It required a single button click. In PLUS 2D you can import single as well as multiple CAD files together. For more detail click here. Click here!! |

||||||||||

|

For more detail Click here!! |

||||||||||

|

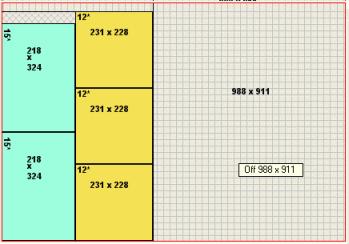

Offcut - a reusable parts that remains from an earlier job. PLUS 2D has an option ' Allow Offcut', where you can specify the minimum area of the Offcut. If during optimization, any optimized layout contains unutilized area having size equal to or more than that, then it is considered as a offcut and it is tracked by PLUS 2D. In summary page 'Total No. offcut' are shown. Also number of Offcuts for a particular row also shown in Layout summary table. And in detail page you can see the offcut position and size. Also if you are using stock from inventory then at the time of updating inventory this offcut will also get added into Inventory , which can be further used in next job. And another good thing is at whenever you are optimizing a Job and in that you are using Offcut generated in a previous job then PLUS 2D first uses that offcut then uses prime stock. See the offcut tracked in the layout. Here offcut size is 988 * 911 |

|

|||||||||

|

Tracking of Offcut |

||||||||||

|

Currently, only regular rectangular shaped offcuts are being stored. We do customize the software to enhance its value for our customers. We may take up this feature after due technical and commercial discussion. |

||||||||||

|

Re-nest - is a special option provided in PLUS 2D. For a particular job after nesting if you don't like the some layouts (more than one ) or you feel there is a better alternative, then you can reject such layouts and Re-Nest that. For details Click Here!! |

||||||||||

|

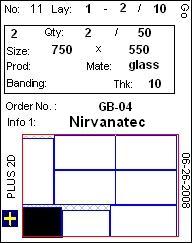

If each part has a label to identify the customer to which is made, its dimensions, etc. the problem is solved. You can add an option to PLUS 2D - link it

with PLUS Label Maker software. This will allow you to make Bar Coded Labels at a click of a button. You can print labels using an ordinary Inkjet, Laser or even Thermal Printer. PLUS Label Maker will print to nearly all PC compatible printers on any type of paper |

||||||||||

|

PLUS Label Maker |

|||||||||

|

PLUS 2D export the layout drawings as DXF with information on different layers which you can import into your cutting table link software. We also write out the data in standard formats. To know whether your CNC controller is supported or not Click Here!! Also if you have any table and to use PLUS 2d along with that please contact with for customization.

|

||||||||||

|

Yes, they can. Many features have been implemented at our clients request. Cost and time vary according to the complexity and exclusiveness of the function to be implemented. If the new feature can be useful to other clients, it could even be implemented free of charge. |

||||||||||

|

PLUS 2D supports links to many CNC cutting machine. To check the list of available Click Here!! If the machine you are using is not present in our list, you can write to us. We will customize PLUS 2D to interface its output with you machine. If you are a CNC based Cutting machine manufacturer or a reseller, we can also offer PLUS 2D as an OEM solution with your saw or cutting table or other cutting machine. Please get in touch with us. |

||||||||||

|

Pattern amendment allows you to edit the nested layout. In some case it happens that there is a big offcut generated in a layout where you want to add another part or some part you want to replace by another parts. This optional add on module in PLUS 2D helps you to edit the desired nested layout. |

||||||||||

|

BOMGen - a bill material software is integrated with PLUS 2D. For more details Click Here!! |

||||||||||

When you have more no of part quantity and want to cut that parts from stock so that wastage will be reduce. If you are trying this manually you will face no of problem, need to lots of calculation, wastage of time, insecurity of perfection. To avoid all this simply switch to PLUS 2D, simple understand, take less time to use and give better output. Using PLUS 2D you can save material and time. |

||||||||||

|

PLUS 2D support only 2 dimensional parts. It only do the nesting of two dimensional parts like nesting from panels, boards, sheet, coils and etc.. so you are not able to see the 3D model. |

||||||||||

|

When you are cutting the stocks/boards into

required sizes, you have to use number of pallets to place different

cut sizes in different pallet. Because of this you will have number

of open pallets, that can waste lots of place, time in keeping the

parts on pallets and energy of the workers doing so. Hence overall

it decreases the efficiency of the process, which may further lead

to delays in delivery. |

||||||||||

PLUS 2D have an optional add on module called Filler Parts. During the nesting of required parts many times big offcuts are remain. Instead of keeping this offcut for later use you can use this offcut directly by specifying the regular used parts (Filler Parts) length. What PLUS 2D will do in this it checks, is there any offcut remain having length larger filler parts length and add part in it. |

||||||||||

|

In PLUS 2D you can specify fine define your own column to add information you required for the documentation purpose, Also you can give name to this column so that its easy to recognize. Most beneficial thing is that if you required to add some data in bar coded labels at time also this column are very useful. |

||||||||||

Whether you are cutting manually or with hydraulic shears or CNC based Punch presses or Gas/plasma machines, PLUS 2D generates cutting layouts or plans that gives you optimum utilization of the stock. They are easy to cut and there is an option - Cut Complexity that helps you to select cutting plans of lesser complexity where required. |

||||||||||

|

Yes PLUS 2D can be interface with ERP system. We can do customization for interfacing with ERP like SAP, BAAN, Ramco, etc. |

||||||||||