Bar Nesting Software - PLUS 1D |

White Papers

|

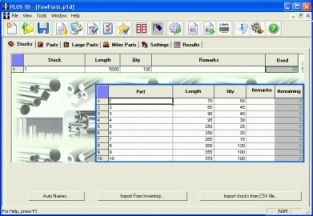

PLUS 1D is a Bar Nesting (multing) optimization software, which helps reduce the waste in cutting any 1D (lineal) material like pipe, bar, angles, sections, flange, rod, tube, channel, frame, profiles, extrusions etc. It automatically generates the optimum cutting plans once the part list, and the available stock has been entered. It has a simple user interface and you get the optimized result, with detailed reports at the click of a button.

Click on Picture for screenshot

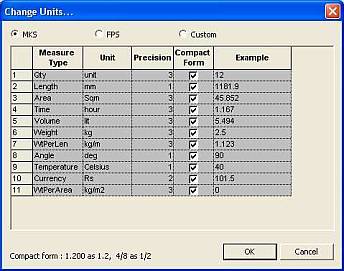

In PLUS 1D you can work in Metric unit or Imperial unit or Custom unit. There is no restriction to work in any specific unit. Also you can switch to any unit though have entered data earlier. Also there is a conversion option to convert any value from one unit to another.

See the Select Unit Dialog

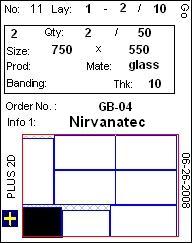

If each part has a label to

identify the customer to which is made, its dimensions, etc. the problem

is solved. You can add an option to PLUS 2D - link it with PLUS Label

Maker software. This will allow you to make Bar Coded Labels at a click of

a button. You can print labels using an ordinary Inkjet, Laser or even

Thermal Printer. PLUS Label Maker will print to nearly all PC compatible

printers on any type of paper

PLUS Label Maker can generate labels for parts and

offcuts. These can be printed for the optimized layouts and for quantity.

The user can design his/her own label. The features of the software

is given below.

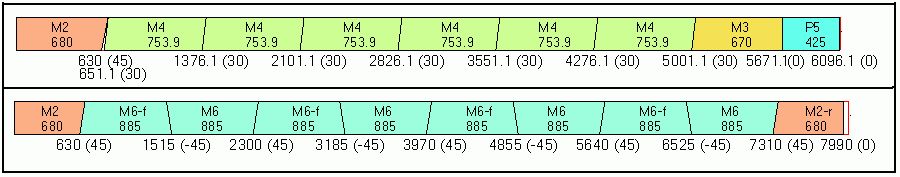

Miter Parts - A 1 dimensional part having slant cut on one or both edges. To nest such parts PLUS 1D has an optional Add on Module called 'Miter Parts'. This is a very simple module to understand and use. You simply add required part with its dimensions like Base Length, Left and Right Angle, Height and quantity. After adding parts do setting and optimize the job, you will get nested output. See the sample layout below for nested miter parts. It giving you total detail info to cut miter parts.

Different Types of Miter Parts

Output of nested miter parts and normal parts

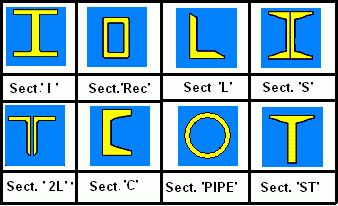

PLUS Section is an optional module which works as database for PLUS 1D. In this module, you can see the sections available in Metric and Imperial Standards. Also you can see the equivalent section for Imperial section in Metric sections and vice versa. You can also define your own list of section which you use frequently.

A sample of sections that are available are shown in figure beside.

For more details Click Here!!

Types of Sections

-

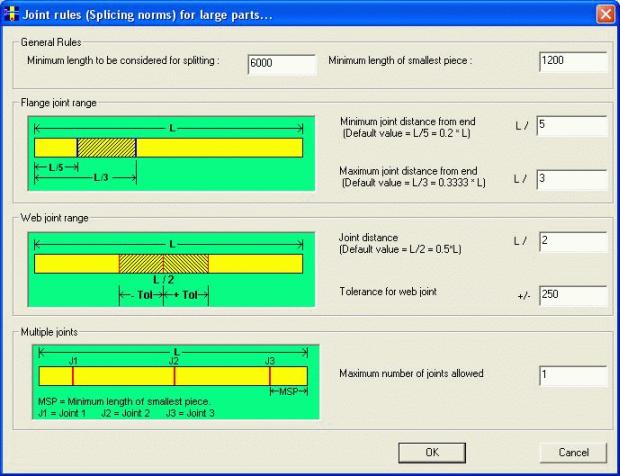

PLUS 1D - Optional Module - Large Parts with Joints - Optimize parts when they are larger than stocks

-

Optimize parts with multiple joints

PLUS 1D have an Optional Add-on Module Large Parts. A part having length greater that stock length is called Large Part. Splitting of Large Parts can be done in PLUS 1D both automatically and manually. During splitting of these parts it follows the standard Splicing norms. Some Splicing norms are constant for particulars type of Large Parts and some can be changed. Take for example a flange. A part of type flange, with length L can be split anywhere between the range L/5 (Minimum Joint Position) to L/3 (Maximum Joint Position). The range decreases if the minimum joint position is less than minimum split piece length by rule. In this case, the range will be between Minimum split piece length to L/3 (max joint position). Only one joint per part is allowed in case of a flange or a web part.

Eg. : If A part of 6000mm is to be split then by rule (L/3 and L/5), splitting range is 1200mm to 2000mm. But if user specifies 1300mm as minimum split piece length then splitting range changes from 1300mm to 2000mm.

For more details Click Here!!

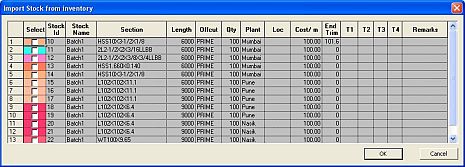

PLUS 1D provides you a built in inventory where you can store different type of stock with there size, cost, weight, quantity and many other properties. Its very easy to handle. Whenever you need to use stock. click button 'Import Stock from Inventory' in Stock Page, a window will open with list of stocks. Mark the Check Box for required stock and click Ok button. After optimization just click on 'Update Inventory' button in Result page, then the used quantity will be reduced and offcuts will be added.

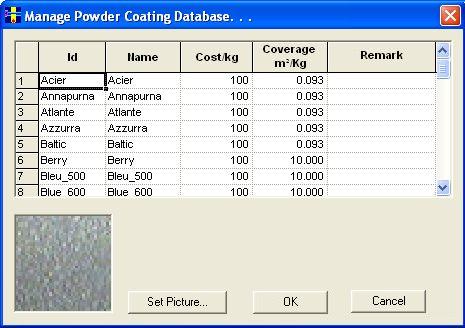

PLUS 1D has an option of Powder Coating. There is a built-in Powder Coating database. Add your powder coating, its coverage , price per kg. Set powder coat for each part and optimize the job. In RTF output file you get the total powder quantity required.

For Details Click Here !!

PLUS 1D always goes for the best solution. If you want estimation of required material for some job then simply add regular stock into stock page with some higher no of quantity, then add parts required to cut then do the required setting and optimize the job. Within few second it will give the no of stock required with best utilization of it.

During the nesting of parts PLUS 1D first uses the offcuts while trying to get maximum utilization then it uses prime stock. In this way the remaining material gets used and both material and money are saved.